GMS-C

Profiler free contour

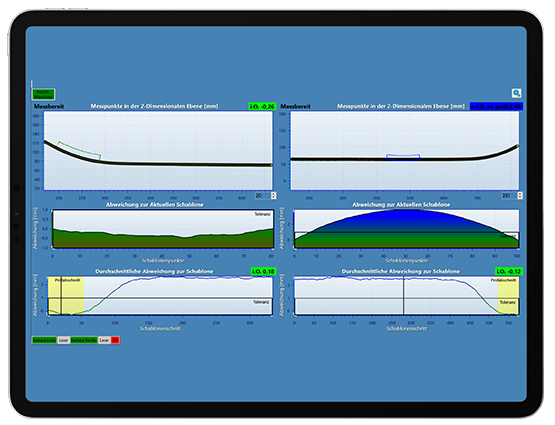

To monitor the curvature of a bent metal plate, the bending shape can be recorded with the GMS-C for comparison with a stored reference geometry.

Measurably precise

Give your product shape

The special feature of our GMS-C is its adaptive design. Depending on the installation situation, we redesign the design and scan perspective. This is the only way we can implement arbitrary and complicated measurement projects. Whether scanning curved sheet metal panels, weld seam geometries or simple height and width dimensions – our GMS-C offers maximum flexibility!

Digital benefits of measured data

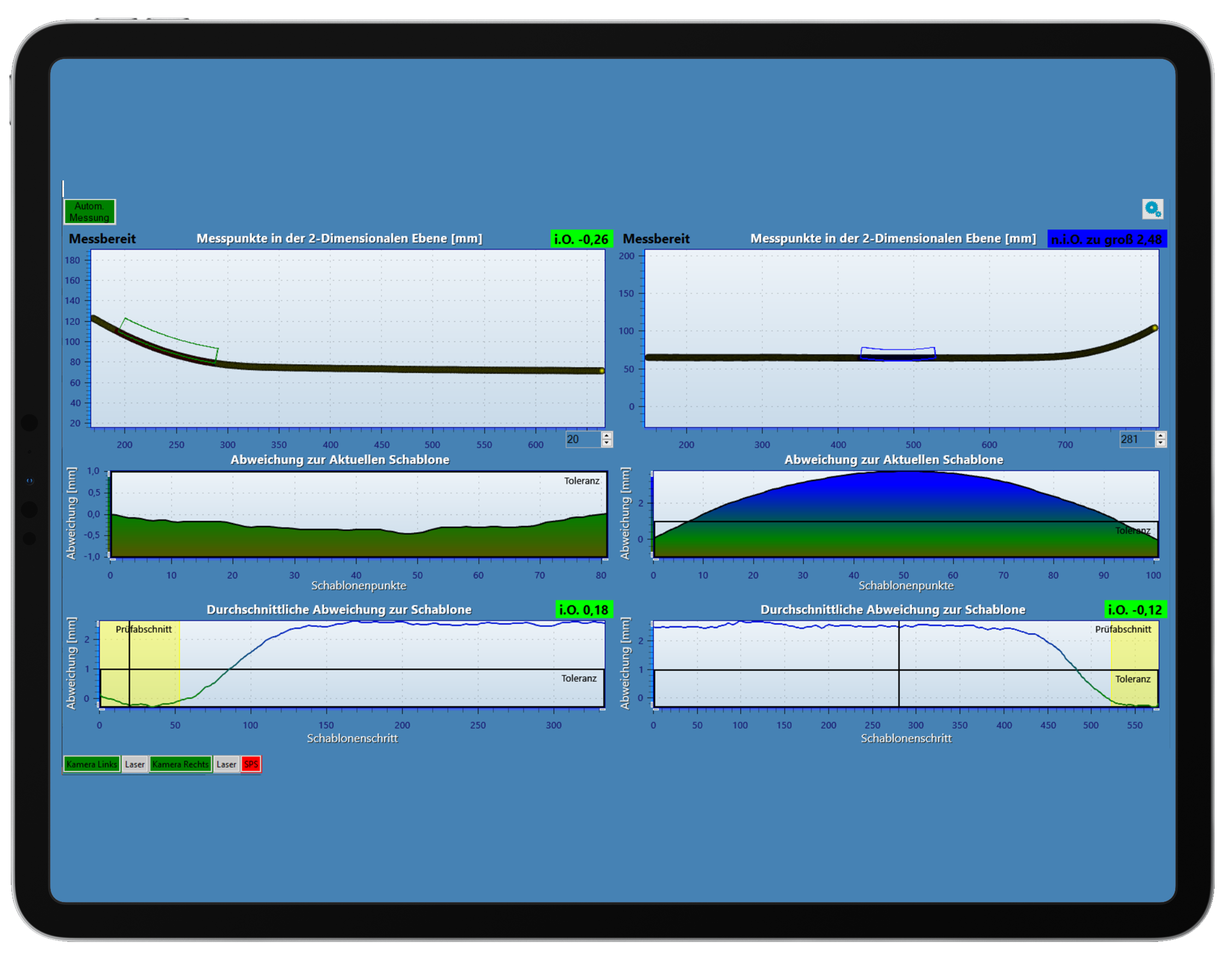

Digitising the contour that you require allows for the simple monitoring of manufacturing tolerances, but above for all direct interaction with upstream or downstream manufacturing processes.

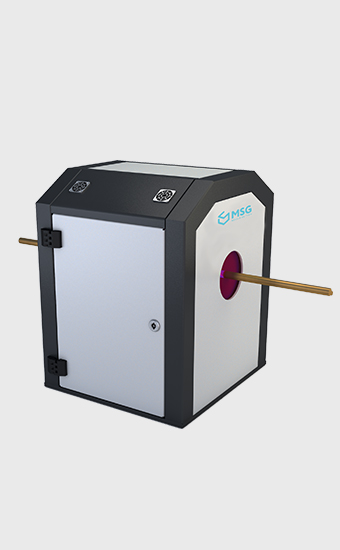

Implementation for industrial applications

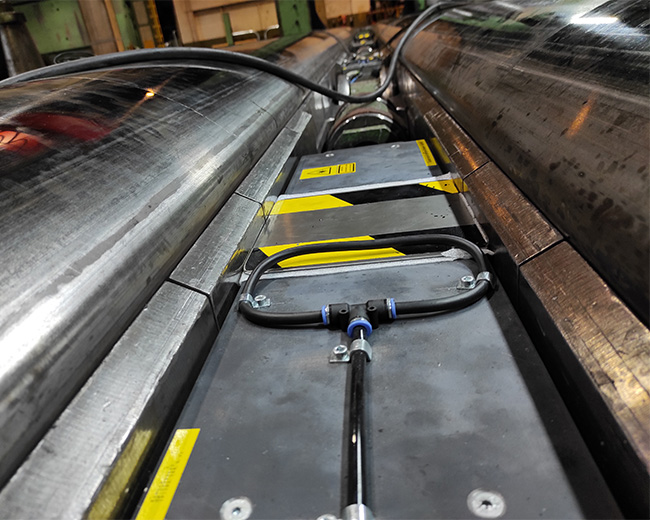

All special constructions of the GMS-C are designed for their surroundings during the project planning. In the harsh industrial environment, tightness and temperature resistance are a must!

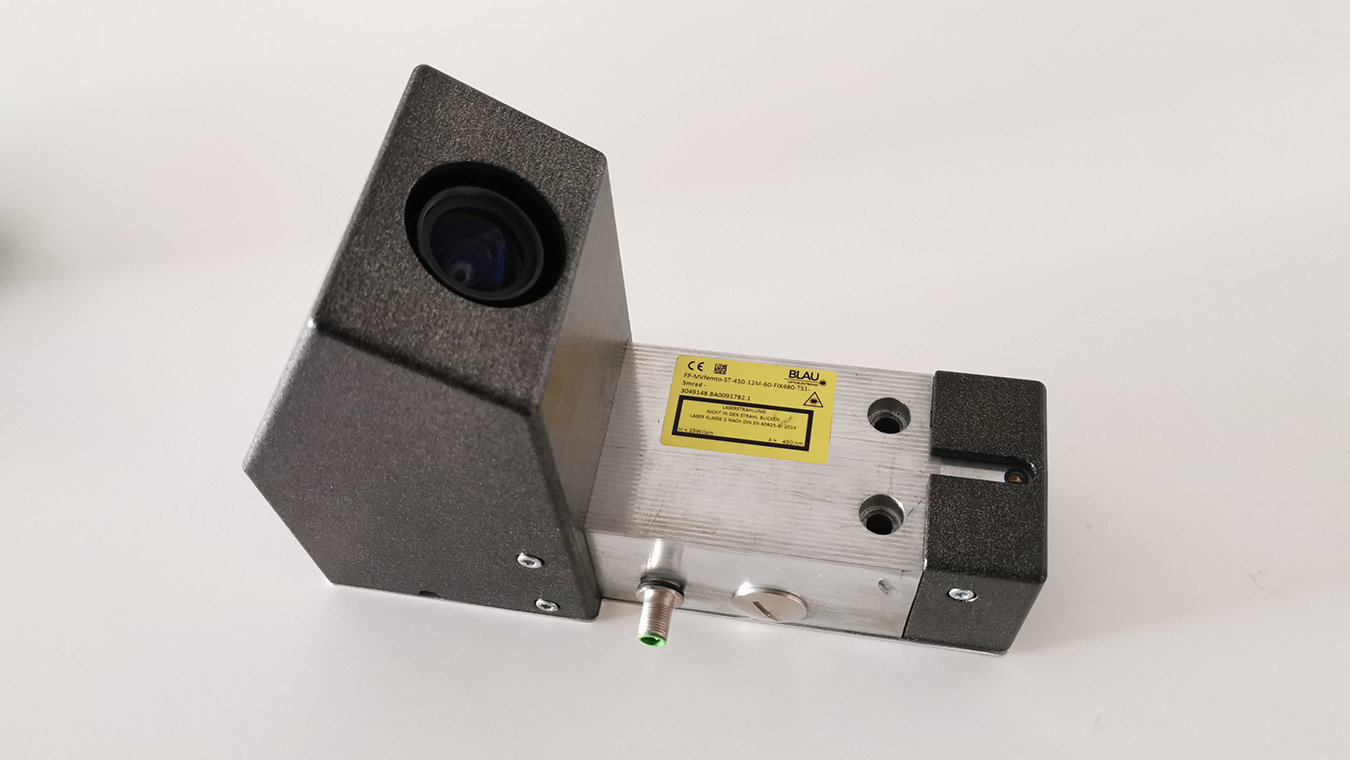

Mechanical adaptability

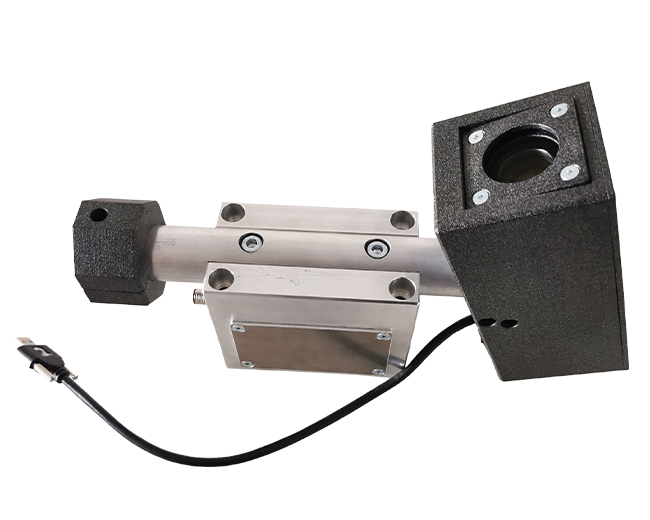

In one particular case, a triangulation measuring head had to be embedded in a flat die of a tube bending machine. By means of mirror deflection, it was possible to digitise a profile with a width of 200 mm despite a construction depth of only 80 mm! Absolutely unique!

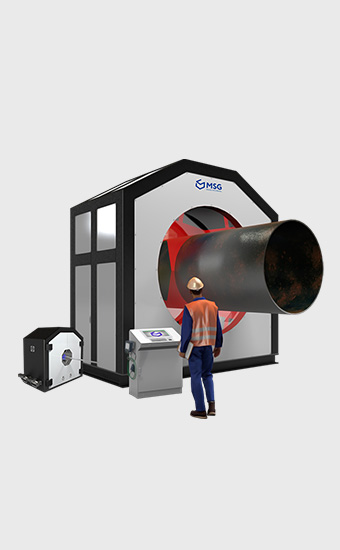

Use case

For radius survey in the bending process, we were able to implement live monitoring of the bending shape at one of our most important customers. For this purpose, an automation system with two of our GMS-C was implemented on an existing press. Thanks to the intelligent design, we were able to realise the digitization of the radius contour within the press!

With the visualisation of your digital data, you always stay on top of things and can use the information for further processing.

Technical data

Application range

- Digitization

- Product certification

- System control

- Production optimisation in bending machines

- Production optimisation in edge rolling machines

- Manual field measurement with a handheld device

- Machine Learning

Product areas

- Linepipe (LSAW, HSAW, Seamless)

- Construction pipe

Materials

- Steel

- Brass

- Aluminium

- Titanium

- a.o.

Integration possibilities

- Free

Inspection criterions

- Radius

- Distance

- Curvature

- General geometric features

Measuring speed

- 200Hz

Measuring accuracy

- Up to 10µm

Interface

- Process: PLC

- Data: SQL

Downloads

Data Sheet (EN)

Data Sheet (DE)

01/04

Similar machines

Take advantage of our know-how and experience to get one step ahead of the competition. Find more solutions here.